We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

Turn your necks to a uniform thickness. Use a neck-wall-thickness gauge to determine the thinnest dimension in your batch of brass, and turn the necks to that size. If your brass has minimal neck-thickness variation (.002 inch or less), you can skip this step.

To figure out the correct bushing size, double your neck-wall thickness and add it to the bullet diameter. Then subtract .001 inch to arrive at the bushing size (e.g., a .308 with .014 inch case walls would take a .335 inch bushing). Or you can measure the outside neck diameter of several loaded cases and subtract .001 neck from the average.

Read Next: How to Build a Compact Reloading Bench

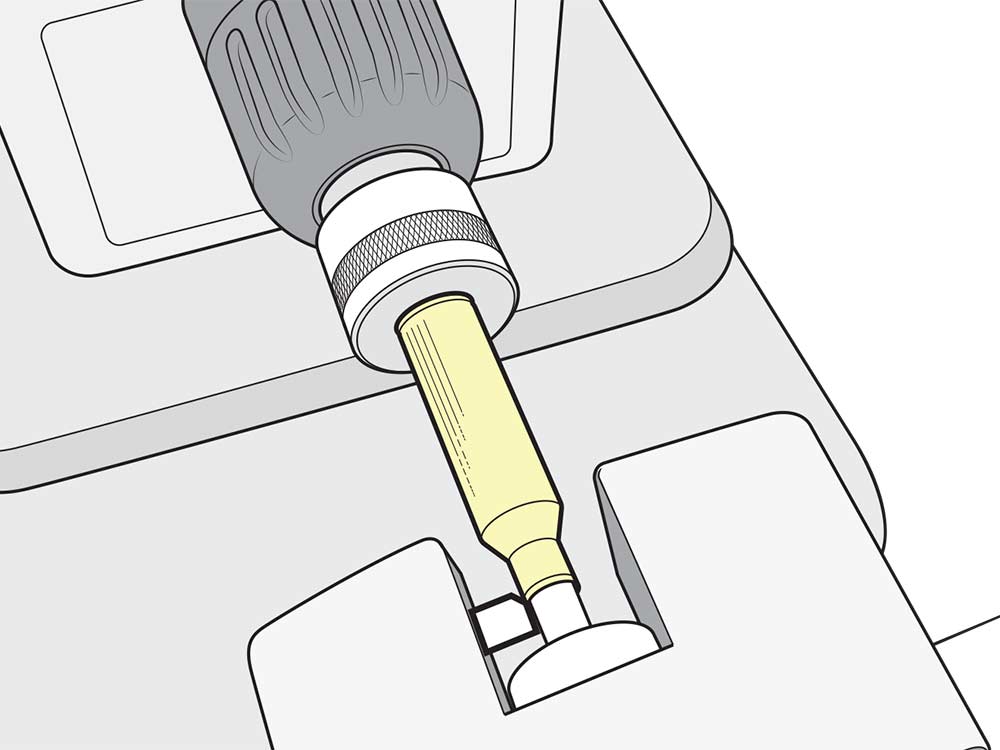

You’ll need bushing dies—available from all major die-makers—in order to use neck bushings. Be sure to chamfer case mouths and lubricate case necks before sizing. Should your cases show signs of getting tight in the chamber, run the brass through a full-length resizing die, which will also resize the neck, or, better yet, a body die, which will resize the brass without altering the neck.